Fieldtrip - Phillipsburg Area

Bus-trip to local AMR probems & solutions

Monday, August 11, 2008

Departs: 11:30 AM from the Ramada Conference Center

Returns: approximately 5:30 PM to Ramada Conference Center

Itinerary:

- Departs: 11:30 AM from the Ramada Conference Center

- 11:50 Stop: I-99 Acid Mine Drainage Mitigation Project, Skytop

- 12:30 Stop: Moshannon DEP Office, Phillipsburg

- 12:50 Stop & Walk: Rushton Large-Scale Active Treatment Facility

- 1: 50 Stop & Walk: Baumgarder Re-mining Active Mining Site

- 2:30 Stop & Walk: "Death Valley": Unreclaimed acid mine drainage Features

- 3:30 Stop & Walk: Bear Hill Passive Treatment System

- 4:10 Stop & Walk: Manor Mine Semi-Active Treatment Facility

- 5:00 Stop: Moshannon DEP Office, Phillipsburg

- Return: approximately 5:30 PM to Ramada Conference Center

I-99 Acid Mine Drainage Mitigation Project, Skytop

Rushton Large-Scale Active Treatment Facility

The Rushton Treatment System protects surrounding areas as it annually pumps and treats aproximately 7 million gallons of acidic, metal laden water daily from the retired Rushton Mine near Phillipsburg. Without this system, water would fill and overflow acid mine drainage from the idle mine workings onto surface areas, potentially causing various types of damage.

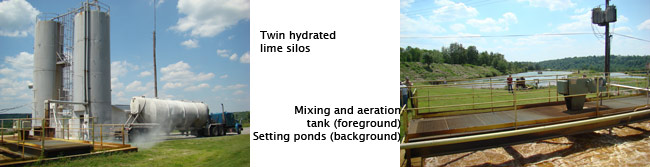

The treatment of the pumped water uses fairly standard industry practices. Hydrated lime stored in silos is added to the flow of water being pumped from the deep mine's voids. That water then flows into a mixing tank where large electric blowers aerate and agitate the water. The hydrated lime neutralizes the acidic mine water and helps promote a reaction where disolved iron combines with oxygen from the blown air to form a rust-like sludge. A fluid know as a flocculant is also added to the mix to make the rust-like particles stick together so they will settle out faster. The water then flowes by gravity to settling ponds where the sudge settles to the bottom of the ponds. The sludge is periodically pumped from the ponds down a shaft into the old mine workings. The water that emerges from the settling ponds is no longer polluted.

While relatively simple in priciple, this operation occurs at an industrial scale. In doing its job the treatment system:

While relatively simple in priciple, this operation occurs at an industrial scale. In doing its job the treatment system:

- annually consumes xxx tons of hydrated lime ( a neutralizing reagent for the acidic water),

- pumps xxx cubic feet of air daily to aerate and facilate the reactions with the polluted water,

- produces and collects xxx tons of iron oxide sludge in 2 x-acre settling ponds,

- consumes approximately xxx kilowatts-hours of electricity daily, equivalant to the usage of about x averge households, and

- costs approximately $1 million dollars every year to operate and maintain the system.

Although the Rushton Mine ended mining operations in 19xx, the mining operator is nonetheless perpetually required:

- to pump water from the mine pool to maintain the mine pool at a safe level, thus protecting surface properties, and

- to treat the pumped and polluted water to "effluent standards" (pH ~7 with very low dissolved metal concentrations)

before it discharges water to Moshannon Creek. Because the mining occurred after the passage of SMCRA in 1977, this site will always be subject to the provisions of the SMCRA Title V active mining regulations.

Baumgarder Remining Active Mining Site

"Death Valley": Unreclaimed acid mine drainage Features

Bear Hill Passive Treatment System

Manor Mine Semi-Active Treatment Facility

_______________________

The Conference Planning Committee thanks the staff of PA DEP's Moshannon office and Dr. Art Rose for making this trip possible.